Rockwool insulation is a high-performance, versatile insulation solution trusted by industry professionals for its superior fire resistance, thermal efficiency and acoustic properties. At FM Insulation, we leverage our 30+ years of experience to supply premium rockwool insulation products for commercial and industrial applications, ensuring optimal energy efficiency and safety for your projects.

What is rockwool insulation?

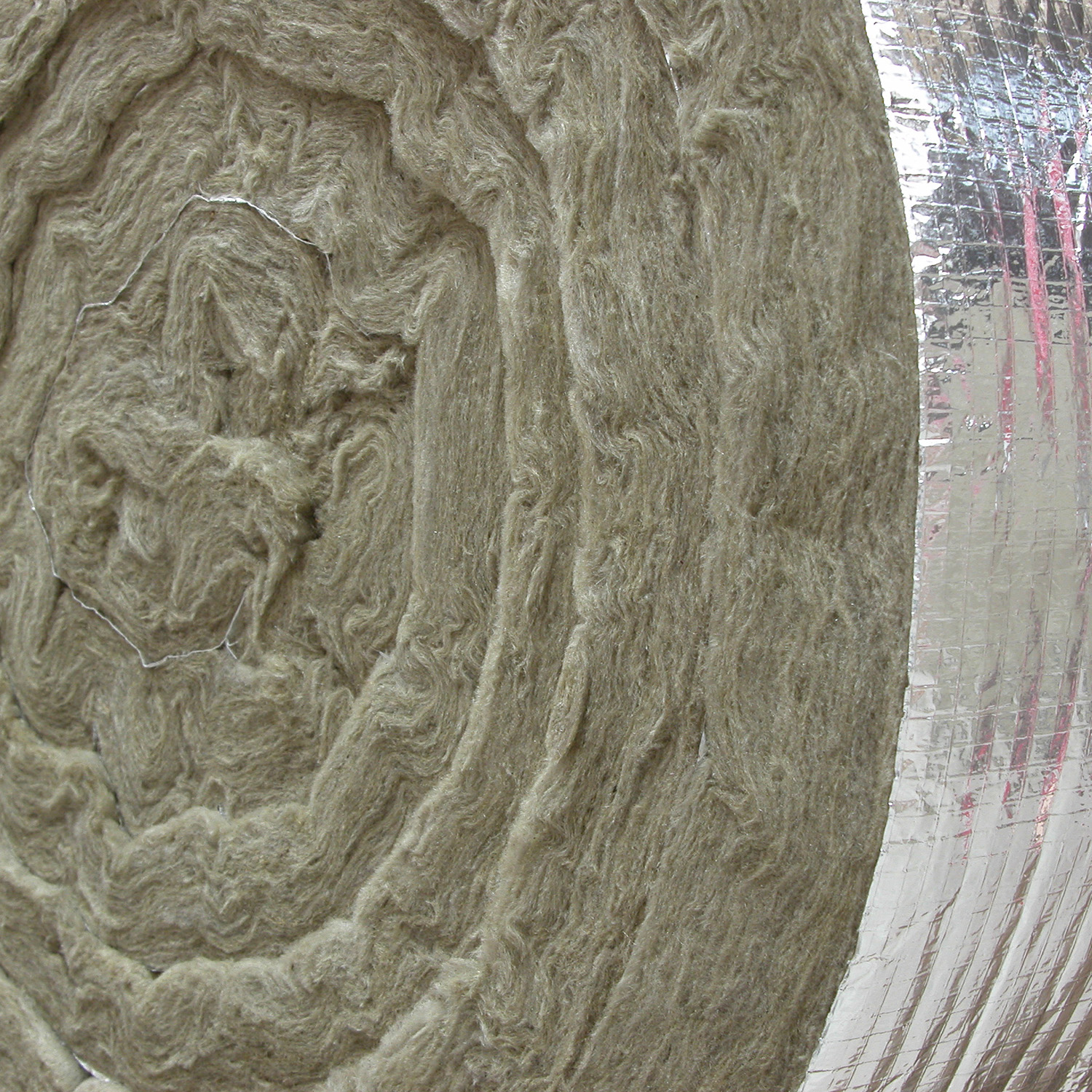

Rockwool insulation, also known as mineral wool or stone wool, is a high-performance insulation material with a rich history dating back to the early 20th century. The concept of mineral wool insulation has its roots in the industrial innovations of the early 1900s.

The manufacturing process of rockwool insulation

The manufacturing process of rockwool involves heating natural rock to extremely high temperatures, melting it into a magma-like consistency. This molten rock is then spun at high speeds to create long, fine fibre strands. These strands are arranged into dense mats and cut to size for various insulation applications.

At FM Insulation, we’ve been supplying rockwool products for over 30 years, witnessing firsthand its evolution and increasing popularity. Known for its excellent fire resistance, Rockwool insulation offers superior thermal and acoustic properties, making it ideal for both commercial and industrial use.

Why choose rockwool insulation?

Rockwool insulation stands out for its exceptional fire-resistant properties, making it an ideal choice for both residential and commercial applications. With our extensive product knowledge, we can help you select the right rockwool solution to meet your project’s specific requirements, whether it’s for thermal insulation, acoustic performance, or fire safety.

Whether you’re working on a power station project, a commercial building, or an industrial facility, our team at FM Insulation can help you select the right rockwool product to meet your specific insulation needs. With our extensive inventory and technical expertise, we ensure you get the right product, at the right price, at the right time.

Energy efficiency with rockwool

Our experience has shown that rockwool insulation is particularly effective in trapping air pockets within its structure, significantly reducing heat transfer and sound transmission. This makes it an excellent choice for projects where energy efficiency and noise reduction are key priorities.

Key benefits and advantages of rockwool insulation

At FM Insulation, we stock a wide range of insulation products, allowing us to provide unbiased comparisons. Our extensive experience has shown that rockwool offers several key benefits and advantages over other insulation types:

Superior fire resistance:

Rockwool can withstand temperatures up to 750°C, providing crucial fire protection. This makes it an excellent choice for industrial applications and multi-dwelling buildings where fire safety is paramount.

Excellent thermal insulation:

Rockwool’s dense structure effectively traps air, significantly reducing heat transfer. This results in improved energy efficiency and lower heating and cooling costs for your projects.

Outstanding acoustic performance:

The unique fibre structure of rockwool absorbs sound waves, dramatically reducing noise transmission. This makes it ideal for use in partition walls, floors, and ceilings in both residential and commercial buildings.

Long-lasting durability and dimensional stability:

Rockwool maintains its shape and performance over time, even under varying temperature and humidity conditions. It doesn’t sag or settle, ensuring consistent insulation performance throughout the life of the building.

Moisture resistance:

Rockwool’s water-repellent properties prevent water absorption, reducing the risk of mould and mildew growth. This is particularly beneficial in high-humidity environments or areas prone to condensation.

Wide temperature range:

Rockwool remains effective from -183°C to +750°C, making it suitable for diverse applications, from cold storage facilities to high-temperature industrial settings.

Chemical stability:

Unlike some foam insulations, rockwool is inert and non-corrosive. This property makes it suitable for use in a wide range of environments without risk of chemical reactions.

Environmentally friendly:

Made from abundant natural resources, rockwool is a sustainable insulation choice. It’s also recyclable, aligning with green building practices and environmental certifications.

Easy to install:

The rigidity and dimensional stability of rockwool makes it easy to cut and fit, streamlining the installation process. Our team can provide technical support to ensure proper installation for optimal performance.

Thermal efficiency:

Its higher density offers better insulation per thickness compared to fibreglass, making it an excellent choice for projects where space is at a premium.

With these benefits and advantages, rockwool proves to be a versatile and high-performing insulation solution for a wide range of projects. Our team at FM Insulation can help you determine if rockwool is the right choice for your specific insulation needs.

Rockwool insulation vs other insulation materials

At FM Insulation, we offer a variety of insulation products, allowing us to provide unbiased comparisons. Here’s how rockwool stacks up against other common insulation materials:

Rockwool vs fibreglass:

- Fire Resistance: Rockwool outperforms fibreglass, withstanding temperatures up to 750°C.

- Sound Absorption: Rockwool offers superior acoustic properties.

- Moisture Resistance: Rockwool is more water-repellent, reducing mould risk.

- Density: Rockwool provides better insulation per thickness due to higher density.

Rockwool vs foam insulations (e.g., polyurethane, polystyrene):

- Chemical Stability: Rockwool is inert and non-corrosive, unlike some foam insulations.

- Environmental Impact: Rockwool is made from natural materials and is recyclable.

- Fire Safety: Rockwool doesn’t emit toxic fumes when exposed to fire, unlike some foams.

Rockwool vs cellulose:

- Moisture Handling: Rockwool is naturally water-repellent, while cellulose can absorb moisture.

- Settling: Rockwool maintains its shape and density over time, whereas cellulose can settle.

- Fire Resistance: Rockwool offers superior fire resistance without additional treatments.

Rockwool vs reflective insulation:

- Temperature Range: Rockwool performs well in a wider range of temperatures.

- Sound Insulation: Rockwool provides better acoustic insulation.

- Versatility: Rockwool can be used in more diverse applications.

While each insulation type has its place, rockwool’s combination of fire resistance, acoustic performance, moisture handling, and longevity makes it an excellent choice for many applications. Our experienced team at FM Insulation can help you determine the best insulation solution for your specific project needs.

FM Insulation Supplies: Your rockwool insulation specialists

With over 30 years in the industry, FM Insulation brings unparalleled knowledge to your insulation needs. Our large inventory ensures quick fulfilment, while our established contractor relationships and broad product range allow us to serve both domestic and international markets effectively. As a family-owned business, we pride ourselves on providing personalised service and technical support to ensure you get the right product, at the right price, at the right time.

Rockwool insulation standards and certifications

Rockwool insulation meets or exceeds various Australian and international standards, ensuring top-quality performance and safety. These certifications underscore the reliability and effectiveness of rockwool insulation products in commercial and industrial applications.

Speak with an insulation specialist or get a quote

Fill out the form below to connect with our insulation specialists. Whether you need technical advice or a customised quote for your project, our team is ready to assist you with our extensive knowledge and experience in rockwool insulation solutions.

Product lines

ROCKWOOL

Foil Faced Mat

ROCKWOOL

Wired Mat

ROCKWOOL SECTIONAL

Pipe Section (available in Plain or Foil Faced)

ROCKWOOL SECTIONAL

Pipe Section with light weight foil facing

Speak with an Insulation Specialist

Frequently Asked Questions

Answers to some of our most common questions.

While rockwool is versatile and suitable for both residential and commercial applications, FM Insulation Supplies primarily works with commercial projects. We specialise in providing rockwool insulation solutions for industrial facilities, multi-dwelling buildings, and large-scale commercial constructions where its fire-resistant and acoustic properties are particularly valuable.

While both are effective insulators, rockwool offers better fire resistance, sound insulation, and moisture resistance than fibreglass. However, it is generally more expensive, reflecting its superior performance in these areas.

Rockwool insulation excels in commercial settings due to its superior fire resistance, acoustic performance, and thermal efficiency. It’s particularly well-suited for large-scale projects like office buildings, factories, and warehouses where safety, energy efficiency, and noise control are crucial factors.

FM Insulation supplies rockwool pipe insulation for pipes ranging from 12.7mm to 323mm (1/2″ to 12″) in diameter. This wide range ensures we can meet the needs of various industrial and commercial applications.

Rockwool insulation can withstand temperatures from -183°C up to 750°C, making it suitable for a wide range of applications, from cold storage facilities to high-temperature industrial settings.

Yes, rockwool is made from natural, sustainable materials and is recyclable. It contributes to energy efficiency in buildings, further enhancing its environmental credentials.

DATASHEETS

Roxul Rockwool

Downloads

- TDS Fire Stop Damper Strip

- TDS Party Wall Fire Stop

- TDS Roxul ProRox BL958

- TDS Roxul ProRox BL960

- Install Party Wall Fire Stop

- Rockwool Cert. of Compl.

Available upon request

- ODP Rockwool

- Formaldehyde Test Certificate Rockwool

- TVOC Test Certificate

- SDS Rockwool

Therm-o-lag Rockwool

Downloads

Available upon request

- AS1530.3 Test Report Therm-o-lag Rockwool

- AS1530.1-1994 Rockwool Combustibility

- SDS Bio Soluble Rockwool Products

- ODP Rockwool Pipe Section

- Formaldehyde Test Certificate Rockwool

- TVOC Test Certificate Rockwool

Paroc Rockwool

Downloads

- TDS Paroc Pro Slab (S80)

- TDS Paroc Pro Wired Mat WR680

- TDS Paroc Marine Wired Mat

- TDS Paroc Pro Mat WR 640 Alucoat Facing

- TDS Paroc Pro Mat WR 660 Alucoat Facing

- Paroc Wired Mat Marine Certificate

Available upon request

- SDS Paroc Rock Wool

- AS1530-1-1994 Rockwool Combustibility

Specifications

- Industries

- Commercial Construction

- Industrial Facilities

- Power Generation

- Oil and Gas

- Food Processing

- Marine and Offshore

- Applications

- HVAC Systems

- Process Piping

- Equipment Insulation

- Acoustic Barriers

- Fire Protection

- Thermal Rating

- R-value range (0.73 to 2.8 in thickness range 25mm to 40mm)

- K-value (thermal conductivity)

- Acoustic Rating

- NRC (Noise Reduction Coefficient) range (e.g., 0.85 to 1.00)

- STC (Sound Transmission Class) range

- Fire Rating

- Non-combustible (AS 1530.1)

- Fire resistance rating (2 hours)

- Temperature Rating

- Operating temperature (-183°C to +750°C)

- Product Forms

- Batts

- Blankets

- Pipe Sections

- Boards

- Density Range

- 40 kg/m³ to 200 kg/m³

- Compliance

- Our rockwool materials comply with all relevant Australian and International standards

- Environmental

- Our rockwool materials comply with all relevant Australian environmental standards

- Whilst old style rockwool was manufactured using recycled materials, modern rockwool materials are manufactured using basalt rock. This ensure a high quality consistent product

- Certifications

- Our rockwool materials are certified to meet the requirements of all major certifying bodies